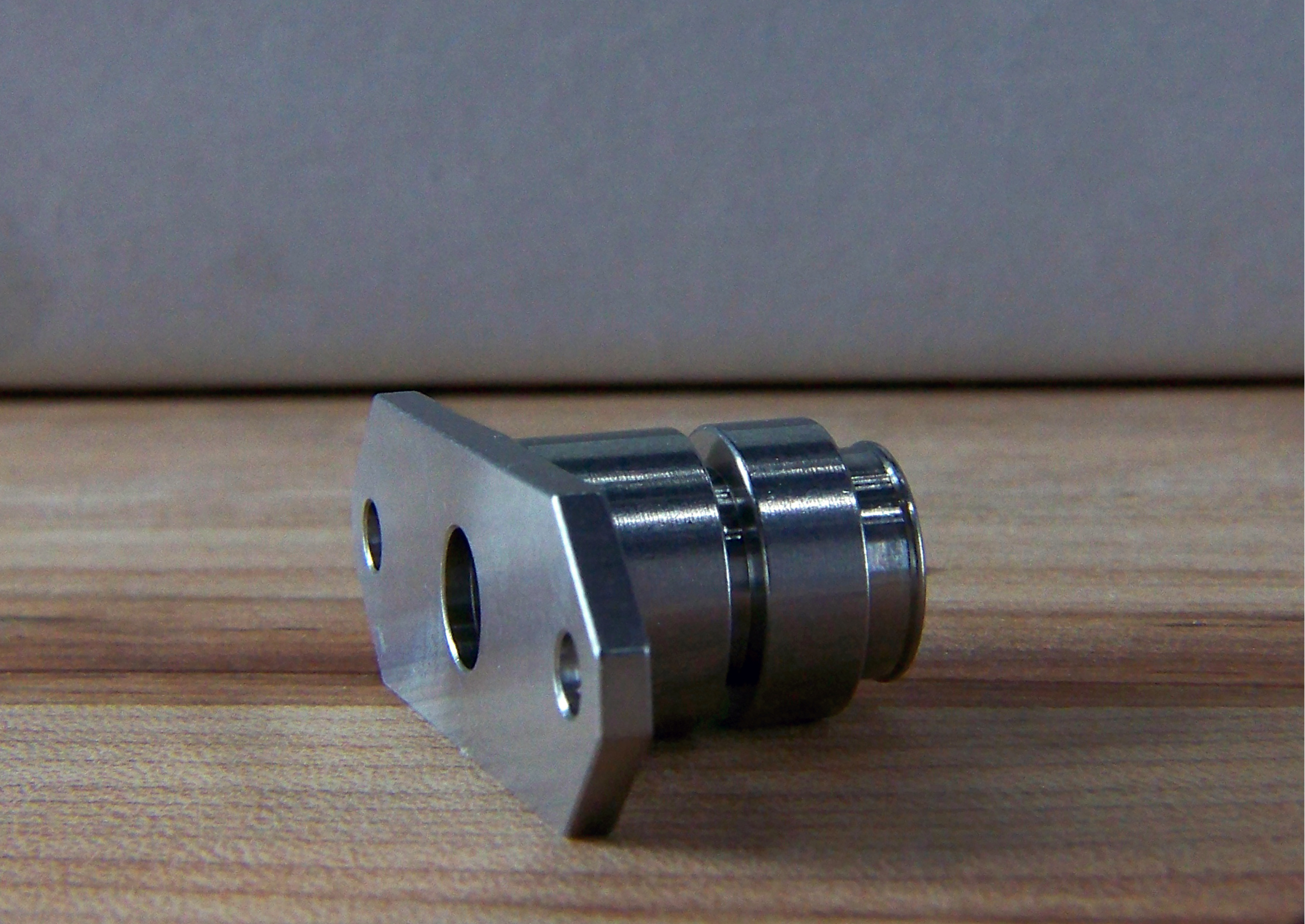

You may not recognize this custom designed part, but it serves a very important purpose! Scroll over the image and read on after the photo to find out more.

Submitted to Lampin as a unique design created by the customer, this end cap pump plate is a component of cosmetic laser equipment, allowing coolant to be pumped throughout the laser assembly to maintain optimal operating temperatures. The part begins as a blank round metal pole of 300 series stainless steel. Lampin’s precision milling equipment is able to mill the part to a +/-.001” tolerance. The head and body are milled in two separate operations due to the differences in shape. The end cap pump plate is then passivated in Lampin’s RoHS compliant citric acid passivate solution. Lampin’s experience with precision grinding and custom manufacturing made them the best choice for this medical device manufacturer’s custom end cap pump plate. For high quality, delicate instruments, such as lasers, it is vital for every component to be made to exact standards for optimum performance and sanitation.