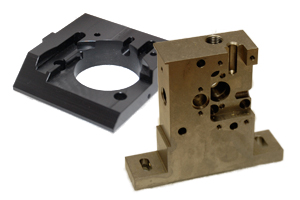

CNC Milling

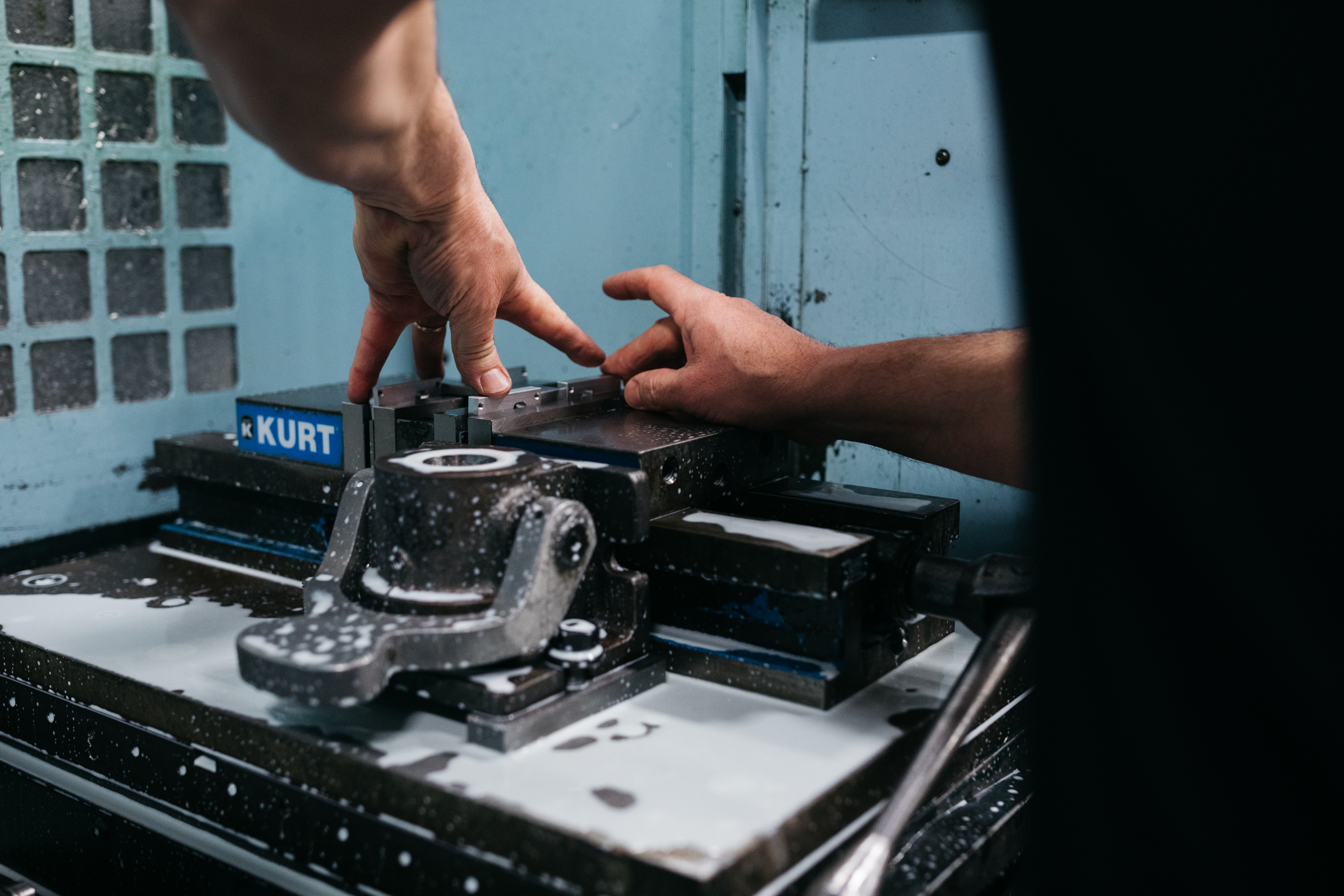

Lampin Corporation provides high-quality CNC milling services for OEMs in a variety of industries, including medical device manufacturing, fiber optic cable manufacturing, semiconductor manufacturing and more. With an array of more than ten different milling machines at our disposal, Lampin is able to utilize traditional milling techniques, combined with modern technology and materials to manufacture critical components with reliable accuracy and efficiency.

Lampin offers a full complement of CNC milling resources with table sizes up to 20” x 40” and fourth axis capabilities. This enables our team to produce precision parts for low-volume, high-mix orders with rapid turnaround, making it easy for us to help you keep your production schedule on track.

Precision CNC Milling Equipment at Lampin

- Hurco VM1 with probe (16 tools)

- Hurco VM20 (20 tools)

- KIWA Triple V21i-rR with auto rotary pallet changer (24 tools)

- KIWA Colt CNC 4 axis Mach. Ctr. w/pallet load (16 tools)

- Matsuura RA-1X CNC with auto pallet changer (30 tools)

- Okuma MC-V4020 CNC (20 tools)

- Tsugami MA-3 CNC with 10 pallets (60 tools)

- Alliant Knee Mill w/Anilam 5300 CNC

- (2) Bridgeport w/42″ Table-Programmable X/Y

- Maxmill w/42″ Table – Hardinge Spacer Unit

- Nichols Twin Spindle Production

- Nichols Hand Miller

CNC Milling Material Capabilities

Our state-of-the-art milling equipment gives us the ability to work with virtually any component material. If required, we are able to source raw materials for you or we can work with the materials you provide. Some materials we commonly work with include:

- Stainless steel

- Aluminum

- Delrin

- Copper

- Brass

- PEEK

- Carbon Steel

Additionally, our experienced team can provide comprehensive engineering support, including material considerations and design input so you always receive the best value for your precision components.