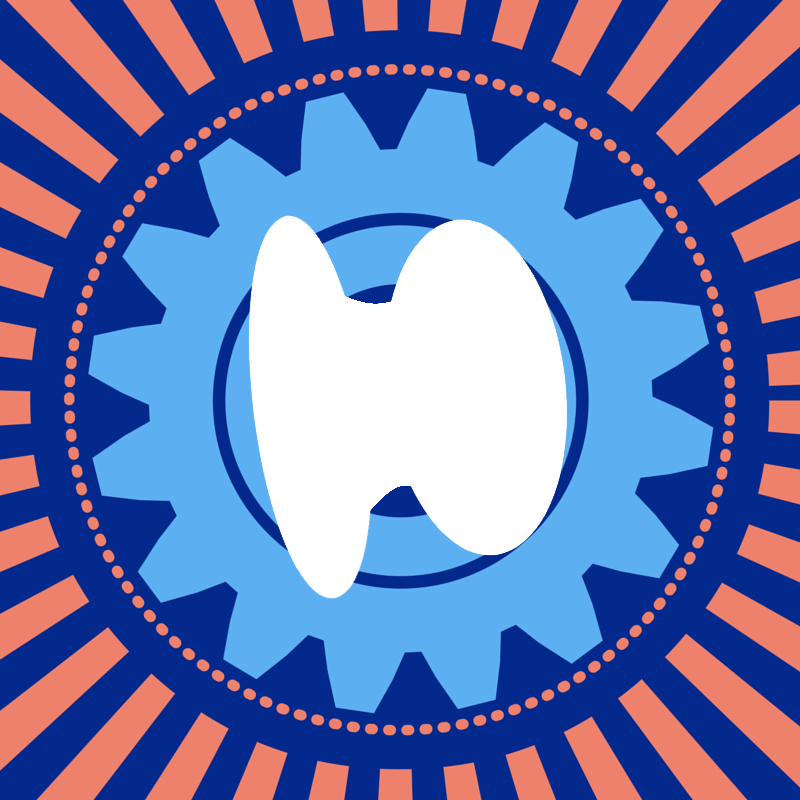

This guide wheel is used in wire printers for custom marking wires and cables. The guide wheel ensures the wires are properly fed into a machine without becoming stuck, out of place, or destroyed. While guide wheels are common machined parts for any equipment that uses cables or wires, this particular part is a custom design sent to Lampin in Uxbridge, MA, for their high quality custom precision manufacturing services. Lampin creates this part by turning 6061 aluminum to shape the guide wheel, and then sends the custom-turned part for a hardcoat anodize. The turned, anodized part is then returned to Lampin, where the bore is honed to .0003” tolerance before finally installing the precision ball bearings. If the guide wheel were not turned correctly the cables could slip or tangle, resulting in messy markings, costly wasted product and scrap, and potentially damaged equipment.