INSTALLATION AND LUBRICATION INSTRUCTIONS

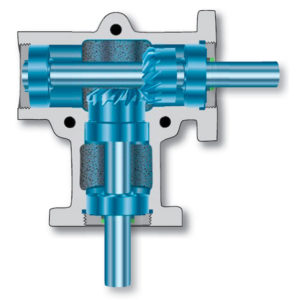

MITRPAK® SPIRAL BEVEL GEARBOX

INSTALLATION

- Confirm shaft rotation before mounting.

- Unit should be mounted using all three (3) mounting holes.

- Accurately align all shafts.

LUBRICATION

Should relubrication be required, use Exxon Nebula EP-O or equivalent.

Caution: excessive amounts of grease will cause the unit to overheat.

REPAIR INSTRUCTIONS

Disassemble:

- Remove all bearing locknuts using spanner wrench.

- Remove driveshaft. Due to cavity between the two bearing support areas, care should be taken to maintain alignment while removing.

- Remove driven shaft in the same manner as above.

Reassemble:

- Thoroughly clean all internal bearing locknut threads in housing.

- Insert driven shaft.

- Insert driveshaft. Note: Bottom front bearing on shoulder.

- Thoroughly clean all bearing locknut threads.

- Assemble bearing locknut on drive leg using Loctite screw lock #242 or equivalent. Note: Excessive sealant in threads may migrate to and cause bearings to seize. Snug bearing locknuts – DO NOT force. Excessive force will preload bearings and reduce life expectancy.

- Assemble bearing locknuts to driven leg using thread sealant as above. Use locknuts to adjust and properly mesh gears.

- Allow sufficient time for locknuts to seal then check using spanner wrench.